Bhopal Disaster - Learnings for Process Safety Management

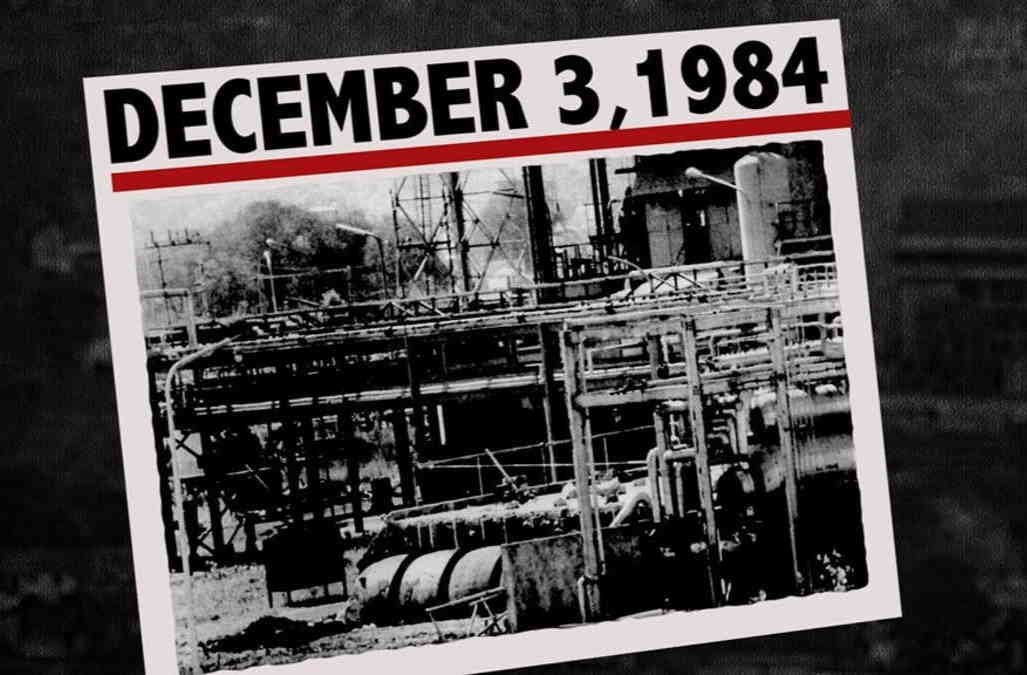

The Bhopal gas tragedy, also known as the #Bhopaldisaster, occurred on the night of December 2-3, 1984, at the Union Carbide India Limited (UCIL) pesticide plant in Bhopal, Madhya Pradesh, India. The incident is considered one of the worst industrial #disasters in history.

The tragedy was the result of a toxic gas leak, primarily methyl isocyanate (MIC), used in the production of pesticides. A combination of factors, including inadequate #safetymeasures, poor maintenance, and cost-cutting measures, contributed to the disaster. The plant's safety systems were substandard, and various #safety protocols were neglected.

In the early hours of December 3, 1984, a significant amount of water entered a storage tank containing MIC, leading to a runaway reaction that caused the release of a #toxic cloud into the air. The gas, which included highly toxic compounds, led to immediate and severe health effects for those exposed.

The impact on the local population was catastrophic. Thousands of people died within the first few days, and many more suffered from severe health issues, including respiratory problems, eye irritation, and long-term complications. The exact death toll remains a subject of debate, with estimates ranging from several thousand to tens of thousands.

The response to the disaster was criticized for its inadequacy. Emergency services were overwhelmed, and there was a lack of proper medical infrastructure to handle the scale of the tragedy. The affected communities faced ongoing health challenges, and the environment around the plant suffered long-term damage.

The Bhopal gas tragedy had far-reaching consequences, leading to increased awareness of industrial safety, environmental issues, and corporate responsibility. The incident prompted discussions on the need for stronger regulations, emergency response preparedness, and legal frameworks to prevent similar disasters in the future. The effects of the tragedy continue to impact the survivors and their families, and it remains a stark reminder of the human and environmental cost of industrial negligence.

The incident resulted in the release of toxic methyl isocyanate (MIC) gas, leading to the loss of thousands of lives and causing long-term health issues for many others. Several lessons can be learned from the Bhopal gas tragedy:

Industrial Safety and Regulations: The Bhopal disaster highlighted the need for stringent industrial safety standards and #regulations. It exposed weaknesses in the regulatory framework and the importance of effective enforcement to ensure that companies prioritize safety over profits.

Corporate Responsibility: The incident underscored the importance of corporate responsibility. Companies must prioritize the safety and well-being of the communities in which they operate. Profit motives should not compromise the safety of workers and the surrounding population.

Emergency Response Preparedness: The inadequate response to the disaster emphasized the importance of having robust emergency response plans in place. Local authorities and industries should be well-prepared to handle emergencies and communicate effectively to minimize the impact on human lives and the environment.

Environmental Stewardship: The Bhopal tragedy drew attention to the environmental impact of industrial accidents. Industries need to adopt environmentally friendly practices, minimize chemical hazards, and take responsibility for the safe disposal of toxic waste to prevent long-term environmental damage.

Community Engagement and Right to Know: The incident highlighted the lack of communication between the company and the local community. People have a right to know about the potential dangers associated with industries in their vicinity. Open communication and community engagement are essential to building trust and ensuring transparency.

Global Cooperation: The Bhopal tragedy had global implications, emphasizing the need for international cooperation in addressing industrial safety issues. Countries and corporations should share information and best practices to prevent similar incidents worldwide.

The Bhopal gas tragedy remains a tragic reminder of the devastating consequences that can arise from a lack of diligence in industrial processes and safety measures. Learning from this disaster is crucial to preventing similar incidents in the future and promoting a culture of safety, responsibility, and accountability in industry and governance.

#bhopal #bhopaldisaster #processsafety #psm #processsafetymanagement #pollutionfree #bhopalgas #methylisocyanate #bhopaltragedy #tragedy #blackswanpk #lessonlearnt #accident #learning