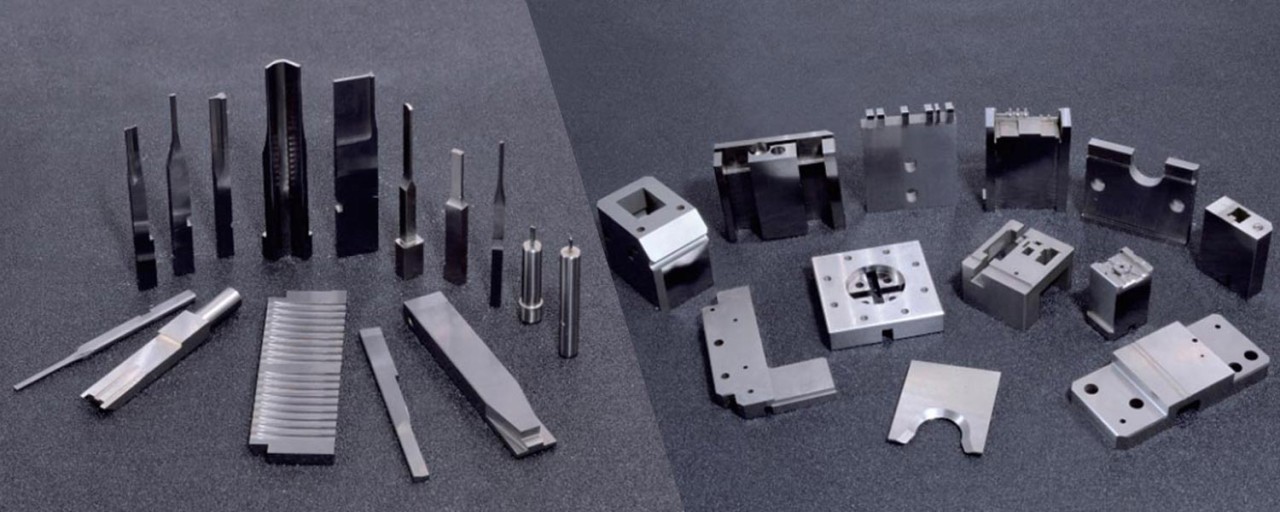

Carbide Punches and Die Inserts for Stamping Tool Press for Connector Terminal Industry

As we know, there are various kinds of industries. One of the top industries is the connectors and terminals industry. It is a microelectronics industry. To make these microelectronics connectors and terminals, we need tools and molds. The most used are metal stamping tool presses. And to make these stamping presses, we need stamping die components. The carbide punches and die inserts are one of them.

With more than 10 years of machining experience in this field. We will discuss some of the details of the carbide punches and die inserts.

Carbide Punches

Carbide punches or called tungsten carbide punches are stamping punches in hard metal materials used in stamping dies and tools. The stamping tools may be single stamping dies, progressive dies, or transfer dies. Or compound dies with various dies combined together for use.

Why use carbide materials?

As we know, the punches are wearable components in the metal stamping dies whether large or small. So harder of the punches, more durable for use.

Actually, hardness is the basic character of the punches. There are also some other factors same important.

One is the accuracy of the punches, more accurate for the punches and dies inserts matched together, and more efficient and durable for use for stamping tools.

Another is the roughness of the punches, the surface roughness control better, it also will be more durable for use.

Then how to control the accuracy and roughness?

It refers to the machining technology and methods and also has some human factors. We need experienced and sophisticated CNC machinists, and we need good machining machines, for example, good brand profile grinding machines, good brand EDM machines, good brand precision plane surface grinding machines, and good brand milling and turning machines. With these combined together, accuracy can be ensured, and with correct machining methods, good surface roughness can be ensured.

Carbide Die Inserts

The same as carbide punches, carbide die inserts also are WC hard metal. They are durable for use. As connectors and terminals are small parts, use stamping molds to make them need even smaller accuracy. So they usually have higher tolerances around +/-0.002mm or even +/-0.001mm than normal components.

As we talked about before, they also need good CNC machinists and good CNC machining machines combined together to do this work.

And some times need good hard metal materials. As there are various kinds of tungsten carbide brands and grades. If you don’t familiar with different brands and grade quality, you may get failed in the first step.

So the make of carbide punches and die inserts is ultra-fine precision work. It needs experiences, equipment and materials combined together. Then we can make these micro stamping die components for stamping tool presses for connectors and terminals.

Stamping Die Components

Except for carbide punches and die inserts, there are also some of the other stamping die components in steel materials, for example, strippers and blocks, most of the stamping die components are rectangular or square shapes. A few of them like guide posts and bushings care circular shapes.

As a die components manufacturer, we accumulate rich experiences in the machining of various kinds of punches, inserts, strippers, blocks, and plates in carbide, HSS, steel, bakelite materials, etc.

More details, welcome to contact us at: sales@langdi-precision.com or phone: +86-15338374626.